Having one or more kayaks is a lot of fun for the family. Storing them at home can be a little tricky. Like any fun toy, they take up space that in most cases is quite limited. That is where creative organization and a separate storage rack is essential. You can easily build your own DIY kayak rack, in under an hour, with our plans using 4×4 posts and plumbers pipe.

One of our favorite activities, at the cabin, is kayaking. Although we started out renting kayaks, it didn’t take long for us to accumulate a few of our own. Because we wanted to keep these kayaks organized and off the ground, we decided to build a kayak rack, outside the garage, for storage. We determined that our rack brackets would be made from one of our favorite materials – plumbers pipe.

Since plumbers pipe can be configured in so many ways, it’s easy to customize brackets for exactly what you need. It’s a little more expensive than making a kayak rack completely from wood. However, the galvanized pipe holds up really well and offers a lot of versatility. In fact, plumbers pipe is often used in a variety of creative DIY projects.

How To Build A Kayak Storage Rack

Supplies Needed To Hold Four Kayaks On Rack

- 2 – 10 foot treated 4×4 posts

- 1 – 55 inch treated 4×4

- 1 – 6 to 8 foot 2×4 for temporary support

- 8 – 3/4 inch steel pipe flanges

- 8 – 3/4 inch by 24 inch steel pipe

- 8 – 3/4 inch by 90 degree steel pipe elbows

- 8 – 3/4 inch pipe connectors

- 8 – 3/4 inch pipe caps

- 32 – 1/4″ x 2″ triple coated construction lag screws

- 4 – #10 5″ triple coated construction screws

- 8 – section of pipe insulation, 3/4 inch by 2 feet

- 2 – 80 pound bags of fast setting concrete mix

- level

- post hole digger

- drill with phillips screw driver bit

- tape measure

Photo Tutorial For DIY Kayak Rack

We started by measuring our longest kayak and then the deepest kayak to determine our rack spacing and piping needs. The pipe that we settled on should be a good size to fit most kayaks. Although the actual construction of the kayak rack goes really fast, you do need to sink the 4×4 posts ahead of time to allow for the concrete around them to dry. It takes approximately 30 minutes to dry but allow a full day to cure. Here is what we did.

Set 4×4 Posts In The Ground

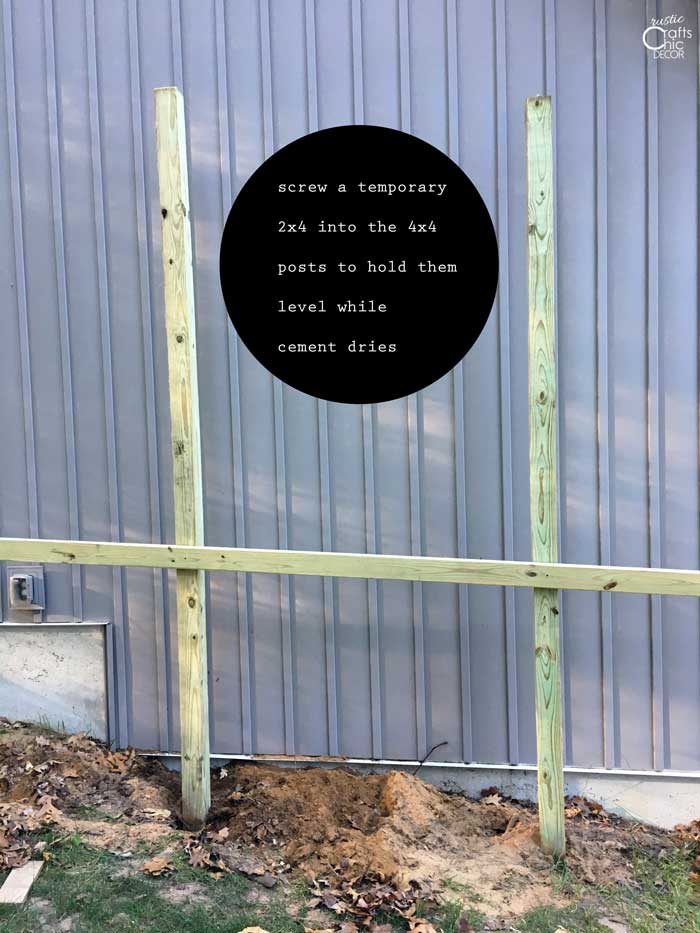

Using a post hole digger, dig two holes about five feet apart, two feet deep, and about 10 inches wide. Starting with one of the 10 foot 4×4’s, set the post in place and pour a bag of concrete mix around it. Use a level to make sure the post is straight. Repeat with the next post. When both posts are level, attach a 2×4 with screws to hold them in place. Pour about two gallons of water over the concrete. Allow to set for about 20-30 minutes. Fill in the rest of the holes with dirt. Let the concrete cure for a day before adding any weight to the posts. You’ve just completed the hardest part.

Attach Pipe Pieces To Form Brackets

This part is super easy. Just screw all of the pipe parts together. Starting with the pipe flange, screw the 24 inch length of pipe into it. Add a pipe connector to the other end. Then, screw the 90 degree elbow into the other side of the connector. Finish the bracket off with a cap at the open end of the pipe elbow. We assembled the full brackets, for just the first two, before attaching them to the wood. For the rest of the brackets, we first screwed just the flange to the wood and then screwed in the rest of the pipe with the flanges in place. You’ll understand why after the next step.

Secure First Two Brackets To Each Of The Posts

Most ground is not perfectly level so you want to make sure the beginning brackets are nice and level. Our kayak rack is actually built on a slight hill. Starting with the post at the highest point. we measured about six inches up from the ground to screw in the first bracket. We then used our 2×4 that had previously been our temporary brace to help us show level. A log put in the middle of the braces and at the same height as the first bracket held the 2×4.

Next, my husband slid the second bracket in place. The flange was behind the 2×4 so that the 2×4 rested on the pipe like the first bracket. After checking for level again, he screwed the flange in place at the bottom hole below the pipe. Then, he removed the 2×4 and secured the rest of the flange holes.

Attach Rest Of Brackets

The rest of the brackets were even easier to install. Now that we had level brackets to work off of, we could just measure from there where we wanted out next brackets installed. Because of the depth of our thickest kayak, we wanted the space between the brackets to be 19 inches. To get 19 inches between each bracket, we measured from the top of the first installed flange, 16 1/2 inches up. This is where we wanted the bottom of the next flange to be and made a mark with a pencil.

Then, holding the flange in place so the bottom butted up with our pencil mark, my husband screwed it in place. Once in place, I just twisted the rest of the bracket into the flange. We repeated this on the other side and then continued in the same way up the post with the rest of the brackets.

Create A Soft Layer For Kayaks To Rest On

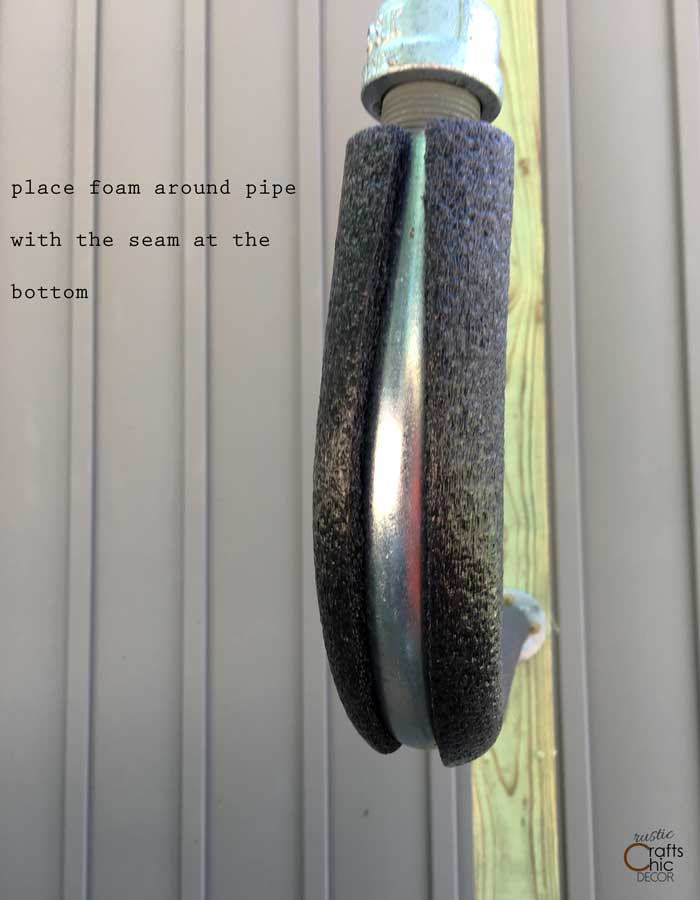

To prevent our kayaks from getting any scratches, while they are on the rack, we added a foam layer. This is easy to do with pipe insulation. We purchased pipe insulation to fit over 3/4 inch pipe. It came in three foot sections which was exactly what we needed for our DIY kayak rack.

For easy installation, I just pulled the foam apart at the seam. This way I could just lay it over the pipe brackets easily.

Once installed, there is a little gap at the underneath side of the bracket. If you don’t want any gaps, you could get a larger pipe insulation like maybe for a 1 inch pipe. Another idea is to use pool noodles for this. That way you could add some fun bright colors to your DIY kayak rack as well.

To hold the insulation in place, we ended up adding zip ties in a couple of areas on the straight pipe. Since we need the elbow piece to twist down at times, we didn’t worry about zip tying the elbow. That is another advantage to using plumbers pipe as our brackets. To slide the kayaks into the rack easily, we turn the elbow down. Once the kayak is in place, we turn it back up.

After we added the zip ties, we cut the long ends off.

Add The Kayaks

For easy kayak insertion, we just bend the elbows of the bracket down. Then, we each take an end and slide the kayak in place. Once in place, the elbows twist back up.

There is room inside each of the elbows of the brackets to also hole the paddles. There was just one thing left to do.

Trim Down The Top Of Posts And Add A Support Beam

After all the brackets, for the DIY kayak rack, were in place, we added a support beam in between the two posts. This would just keep everything more secure and sturdy. The measurement between the insides of the two posts was 55 inches. We cut the third 4×4 to 55 inches to butt into the insides of the posts. To secure the 4×4, my husband screwed from the outside of the post into the beam using a couple of five inch constructions on each side. Then, it was on to trimming down the posts.

Since we were working on a hill, it was harder to know what size to cut each post. The sizes would be different because the ground was at a different level on each side. Instead of trying to figure out our sizes beforehand, I suggested cutting the posts after everything was installed. Again, we used our 2×4 to determine level. We clamped the 2×4 to each post at level. Then, we simply marked a line below the 2×4 with a pencil. After that, it was just a matter of cutting on the line with a chain saw.

Finished DIY Kayak Rack

We left room for one more kayak! To make use of all available storage space, we added a “u” hook to each post at the top outer side. This makes a great space to store our paddle board paddles.

While I really appreciate this article being posted, I regret to say that this was a bit of a fail for us, and it wasn’t very budget-friendly. My husband built this a couple of months ago for our 2 kayaks (10′ and 12′), and within the first month, the bars were already sagging and the flanges were rusting out. We also had one of the bars snap off at the flange, causing the threading to get stuck inside the flange. I thought this was a great concept, but unfortunately it won’t last long for us. We live in the very humid climate of north Georgia though, so…

This looks like a great idea! Like the design really well, and it would work well on the side of our shed. We live in the woods, and one problem we can seem to figure out how to work around is keeping mice and wasps from building their nests in the yaks. Have you addressed this issue where you live?

I’m glad you like the design! We have not run into a problem so far with either mice or wasps.

I wonder if there was a way I could make this but have make it freestanding by adding cross support 2×4’s or 2×6’s and designing some sore of legs with 4×4’s or 2×6’s?

I was looking at this design for 2 kayaks to mount on the side of my wood park trailer. Thought I would find the struts and drill through the siding and mount 2 2 by 4’s with 4 in. exterior screws and then mount 4 pipe flanges and the rest. Any concern that the struts and siding might not hold?

Hi, I tried something similar but the 4×4 pressure treated broke near the groundline. Next time I would use 4×4 sleeves (protects the wood underground) and not cement into the ground to prevent the wood from degrading and breaking. I didn’t use the sweeps, not necessary. Otherwise this is a great rack design if you don’t have the option of a garage or out building wall to attach to.

This is exactly what I was looking for. What is the width of your widest kayak/canoe and how heavy is your heaviest kayak/canoe?

Planning to do the same, but inside a shed/boathouse which I am purposely framing with 4×4 studs so I will be able to just screw into those. Curious to know how solid this feels – 4 screws holding the flange have to carry not only the static weight but also the impulse loading when you put the kayak in place? Also, I am not sure that I really see the need for the 90-degree end pieces – do kayaks not stay put on cushioned horizontal pipes? Seems to me that straight pipes would make loading easier. Feedback is appreciated.

Hi John! The kayak rack feels real solid and we haven’t had any issues with it. And yes, straight pipes should work out just fine!

Exactly what I was looking for. Matched the design we drew from scratch to a tee! Thank you.

Fantastic! Good luck with your project!

What a great idea. I’m going to do this just as you said. I can’t thank you enough. 🙂

You’re welcome! I’m glad you found the idea helpful!

This is a great idea and may want to do something like this on my privacy fence. Any issues with the pipe rusting? Thanks!

We haven’t had any rust so far and it’s been almost a year.

Those pipe elbows you used on your kayak are called “Sweep Elbows” or “Long Sweep Elbows”, and are not sold in your average big-box hardware store. I am sure people can find them online or at a plumbing supply house, as long as they know how to specify them, but it might be worthwhile modifying your materials list to help them out.

They do look much nicer and gentler on the boats than a regular 90 degree EL.

Thank you. We did purchase our elbows from a big box store, Menards, and they were just labeled as 90 degree elbows. It’s helpful to know the other name though!

Do those pipes hold that weight and not sag at all?

Yes they do. We haven’t had any sagging at all!